歐帕集團(tuán)——專注于建材磚瓦行業(yè)“切、碼、運(yùn)、打包”全流程方案解決的工業(yè)智能化設(shè)備制造商。集團(tuán)下轄河南歐帕工業(yè)機(jī)器人有限公司、開封歐帕自動(dòng)化有限公司兩大核心產(chǎn)業(yè)基地,占地近200畝,廠房面積超過90000㎡,具備強(qiáng)大的生產(chǎn)加工能力,是全球制磚自動(dòng)化裝備的重要支撐力量,累計(jì)服務(wù)國內(nèi)外客戶超過23000家。

OMPA Group is an industrial intelligent equipment manufacturer that focuses on providing full-process solutions for the "cutting, palletizing, transporting, and packing" in the building materials and brick-tile industry. The group has two core industrial bases, namely Henan OMPA Industrial Robot Co., Ltd. and Kaifeng OMPA Automation Co., Ltd. Covering an area of nearly 200 mu and with a workshop area of over 90,000 square meters, it has a strong production and processing capacity. It is an important supporting force in the global automatic brick-making equipment field, and has served more than 23,000 domestic and foreign customers in total.

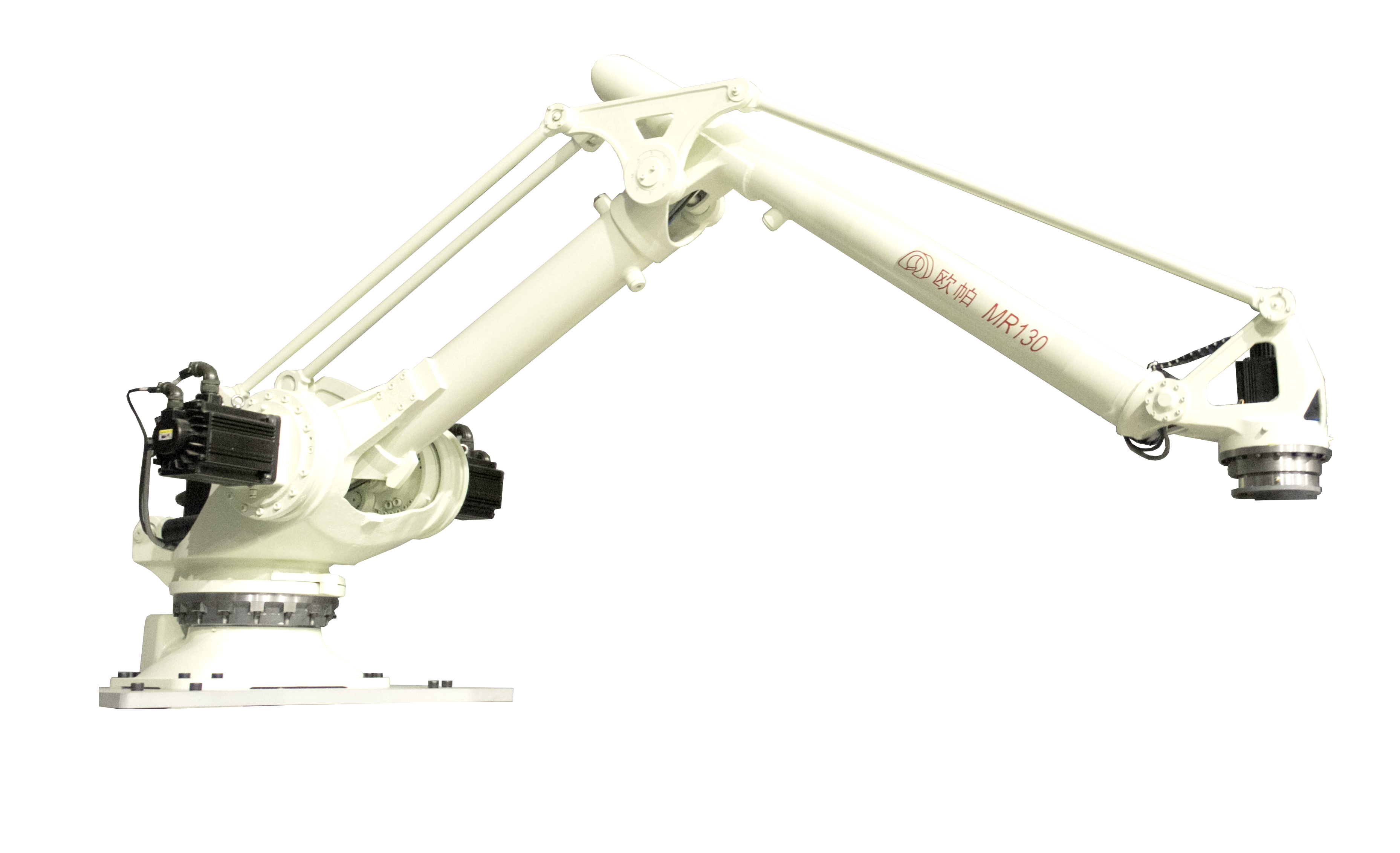

歐帕專業(yè)致力于磚瓦行業(yè),集自主設(shè)計(jì)、研發(fā)、生產(chǎn)和銷售于一體,具有豐富的工程案例設(shè)計(jì)實(shí)踐經(jīng)驗(yàn)。所有產(chǎn)品都基于自主開發(fā),獨(dú)立創(chuàng)新,引領(lǐng)行業(yè)技術(shù)模式,擁有完全自主知識(shí)產(chǎn)權(quán),主要零部件及關(guān)鍵技術(shù)完全自主化,具備強(qiáng)大的技術(shù)優(yōu)勢及市場競爭力。獨(dú)立研發(fā)負(fù)載1.6噸的機(jī)器人本體,創(chuàng)新技術(shù)路線,實(shí)現(xiàn)重載機(jī)器人輕量化目標(biāo),自重及能耗不到同類產(chǎn)品一半,以高速度、高效率、高負(fù)載的突出特點(diǎn),推動(dòng)工業(yè)制造邁入節(jié)能環(huán)保新境界。

OMPA is professionally dedicated to the brick and tile industry, integrating independent design, research and development, production, and sales. It has rich practical experience in engineering case design. All products are based on independent development and innovation, leading the technological model of the industry. With complete independent intellectual property rights, the main components and key technologies are fully autonomous, giving it strong technical advantages and market competitiveness.

OMPA has independently developed a robot body with a load capacity of 1.6 tons. Through an innovative technical approach, it has achieved the goal of lightweight heavy-duty robots. Its self-weight and energy consumption are less than half of those of similar products. With the outstanding features of high speed, high efficiency, and high load capacity, it has propelled industrial manufacturing into a new realm of energy conservation and environmental protection.

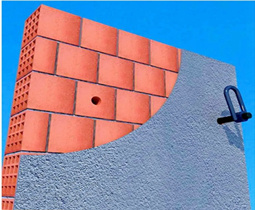

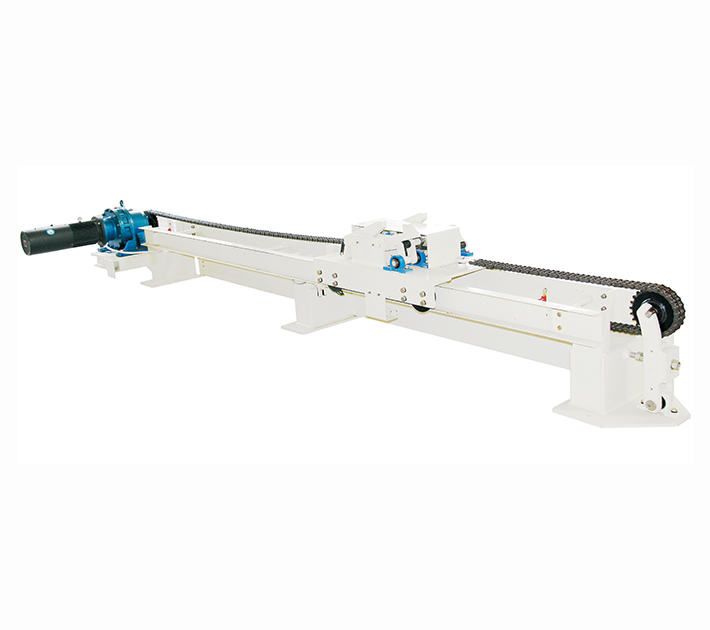

集團(tuán)始終以客戶需求為創(chuàng)新驅(qū)動(dòng),以定制化產(chǎn)品和多樣化方案主導(dǎo)市場。基于重型碼垛機(jī)器人開發(fā)的4軸、5軸機(jī)器人,負(fù)載覆蓋130Kg——1600Kg,通過多功能機(jī)械手結(jié)構(gòu)調(diào)整,已實(shí)現(xiàn)在建材板材、建筑砌筑、打包包裝、食品飲料、糧食飼料、化工涂料、加工鑄造等高強(qiáng)度、高風(fēng)險(xiǎn)作業(yè)場景的配套使用,可大幅提高工作效率、降低生產(chǎn)成本。典型應(yīng)用場景入選2022年中國國家工信部《建筑領(lǐng)域機(jī)器人應(yīng)用優(yōu)秀場景名單》。公司持續(xù)引領(lǐng)行業(yè)技術(shù)革新,原創(chuàng)的全自動(dòng)切割、隧道窯磚坯碼垛、移動(dòng)隧道窯碼垛生產(chǎn)線等都成為行業(yè)基本模式,累計(jì)銷售超過25000條生產(chǎn)線。近年推出的半自動(dòng)和全自動(dòng)拆垛、打包生產(chǎn)線高效快捷穩(wěn)定,打通了制磚自動(dòng)化生產(chǎn)最后一公里,成為用戶追逐的熱銷產(chǎn)品。系列設(shè)備支撐起了現(xiàn)代磚廠的高效運(yùn)轉(zhuǎn),引領(lǐng)燒結(jié)磚行業(yè)基本實(shí)現(xiàn)無人化。

The group has always taken customers' needs as the driving force for innovation and dominated the market with customized products and diversified solutions. The 4-axis and 5-axis robots developed based on heavy-duty palletizing robots have a load range covering from 130Kg to 1600Kg. Through the structural adjustment of the multi-functional manipulator, these robots have been applied in high-intensity and high-risk working scenarios such as building materials plates, building masonry, packaging, food and beverages, grain and feed, chemical coatings, and processing and casting. They can significantly improve work efficiency and reduce production costs. The typical application scenarios have been selected into the "List of Excellent Robot Application Scenarios in the Construction Field" released by the Ministry of Industry and Information Technology of China in 2022.

The company continues to lead the technological innovation in the industry. The original fully automatic cutting, tunnel kiln green brick palletizing, and mobile tunnel kiln palletizing production lines have all become the basic models in the industry, with a cumulative sales volume of more than 25,000 production lines. The semi-automatic and fully automatic unstacking and packing production lines launched in recent years are efficient, quick and stable. They have bridged the last link in the automated brick-making production process and become hot-selling products that users are eager to purchase. The series of equipment ensures the efficient operation of modern brick factories and leads the sintered brick industry to basically achieve unmanned production.

歐帕專注于為用戶提供最優(yōu)秀的產(chǎn)品和最貼心的服務(wù),始終緊密跟進(jìn)市場需求,精準(zhǔn)捕捉行業(yè)趨勢,致力打造用戶體驗(yàn)。我們將繼續(xù)以科技創(chuàng)新為驅(qū)動(dòng),以用戶需求為引領(lǐng),與廣大磚企攜手,共同創(chuàng)造節(jié)能、高產(chǎn)、低排放的智能制造新時(shí)代。

OMPA is dedicated to providing users with the best products and the most considerate services. It always keeps a close eye on market demands, accurately captures industry trends, and is committed to creating an excellent user experience. We will continue to be driven by technological innovation and guided by users' needs. Hand in hand with numerous brick enterprises, we will jointly create a new era of intelligent manufacturing featuring energy conservation, high yield, and low emissions.